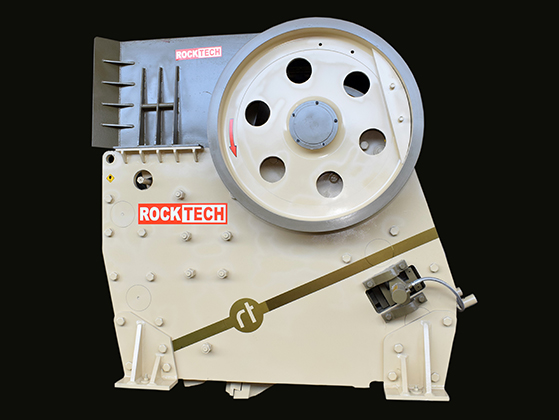

JAW CRUSHER

Jaw Crusher Exporters

RT Jaw crushers are designed to operate in most rugged environment and need less maintenance for all types of rocks, mineral ores. These single toggle jaw crushers are designed with an downward facing toggle system, which guarantees a high efficient production rate at every setting. Jaw crusher exporters and manufacturers in Mumbai, India to all over the world jaw crushers industry in low price with reliable and durable features.

Benefits & Features

Designed for effective crushing for bigger feed sizes with large crushing ratio to give optimum product shape, Longer life for jaw plates and other components, Due to built-in features like no jerks, rubbing action and Hydraulic adjustment of CSS Relatively simpler and smaller design hence can save on foundations, components and service Costs. Grease lubricated self-aligning double row roller bearing Lubrication free toggle and toggle seat with minimum friction, Large crushing chamber, longer stroke and high crushing speed.

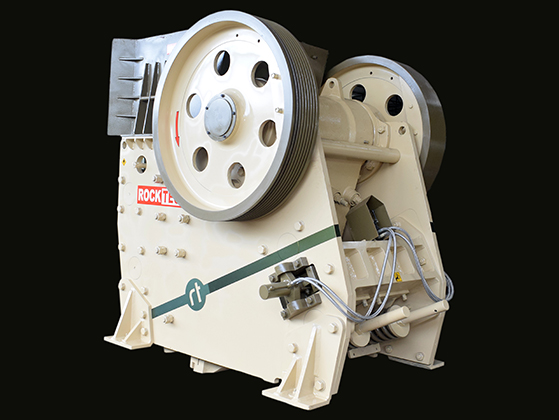

Industrial Jaw Crusher

The industrial Jaw Crusher is widely used in order to crush materials of varying hardness (such a high, mid and soft ores) such as iron ore, slag, marble and other construction materials. The machine we're centered around the primary crushing of materials and subsequently can be utilized as a machine to crush huge stones consistently. They're normally found in industries like mining, street building, rail route building, hydraulic, construction, metallurgy, smelting and chemical industries.

The Jaw Crusher depends on a revolutionary measured, non-welded frame construction - this at that point offers proprietors and customers the most elevated conceivable fatigue strength while keeping up astounding reliability and a colossal number of mounting opportunities for use across numerous industries. As a result of the finely adjusted construction, this industrial machine can be one of the simpler and most conservative kinds of crushing machine to install and actively start utilizing. Combined with the special high-quality cast steel components and the very durable to wear parts, this means exceptionally high crusher availability, very cost-efficient crushing and a surprisingly low cost per ton. To sum up, according to Jaw Crusher exporters jaw crusher has a simple structure, which brings about easy maintenance as a result, a stable performance and even for the final particles with a high crushing ratio.

Jaw crusher exporters, manufacturers in Mumbai, India to all over the world jaw crushers industry according to the client's need and suggestions with long lasting and low maintenance.

Technical Specification

| Model of Jaw Crusher | Feed Opening size(mm) | Max. Feed size (mm) | CSS (mm) & Throughout Capacity(TPH) | Power (KW) | RPM | |||||||

| 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | |||||

| RTJ50 | 900 X 750 | 650 | 75-85 | 85-125 | 125-150 | 150-180 | 75 | 275 | ||||

| RTJ60 | 1100 X 750 | 650 | 105-170 | 155-230 | 180-275 | 210-315 | 245-360 | 285-460 | 110 | 250 | ||

| RTJ70 | 1150 X 850 | 750 | 165-240 | 200-305 | 230-385 | 265-405 | 310-495 | 340-515 | 135 | 235 | ||

| RTJ80 | 1250 X 900 | 800 | 190-285 | 235-345 | 265-405 | 295-445 | 340-540 | 370-560 | 400-585 | 150 | 225 | |

Rocktech Engineers is one of the best Jaw Crusher Exporters, Suppliers, Manufacturers in India.

NOTE: Due to the difference of rocks and the size percentage, distribution and the practical capacity will be different.